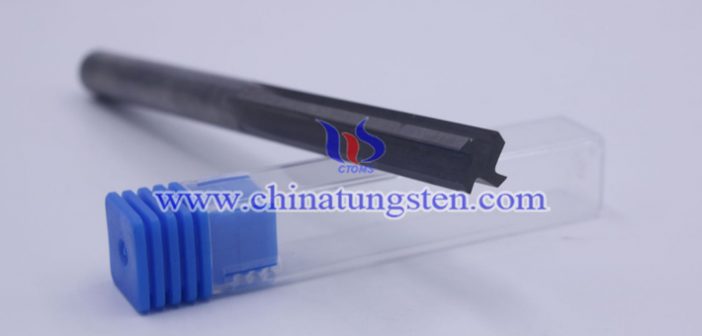

Tungsten carbide reamer is a rotary cutting tool for processing different workpiece materials such as aluminum, brass, cast iron, mild steel, plastic and stainless steel, etc. Wherein, aluminum and brass are typical workpieces with good to excellent machinability ratings; Cast iron, mild steel and plastic have good ratings; Stainless steel has a poor rating because of its toughness and it tends to work harden as it is machined.

More details, please visit:

http://www.tungsten-carbide.com.cn/tungsten-carbide-blade-bar.html

Tungsten carbide reamer with high precision is designed to enlarge the size of a previously formed hole by a small amount but with a high degree of accuracy to leave smooth sides. And non-precision reamer is used for more basic enlargement of holes or for removing burrs.

There are different types of tungsten carbide reamers, such as, tungsten carbide hand reamer and tungsten carbide machine reamer. A hand reamer has a longer taper or lead in at the front than a machine reamer to compensate for the difficulty of starting a hole by hand power alone. A machine reamer only has a very slight lead in. Because the reamer and work piece are pre-aligned by the machine there is no risk of it wandering off course.