Compared with common blank bar, it has better performance in roughness and surface quality. And common copper electrode has large consumption, low precision and efficiency when processing tungsten carbide, high carbon steel, hardened tool steel, while tungsten copper has greatly improved the efficiency and accuracy. Tungsten copper not only has good electrical conductivity, high soften temperature, wear and corrosion resistance, long service life and low frequency of electrode correction, but also save the production costs based on improving efficiency.

More details of tungsten copper polished bar please visit http://www.tungsten-copper.com/tungsten-copper-bar.html

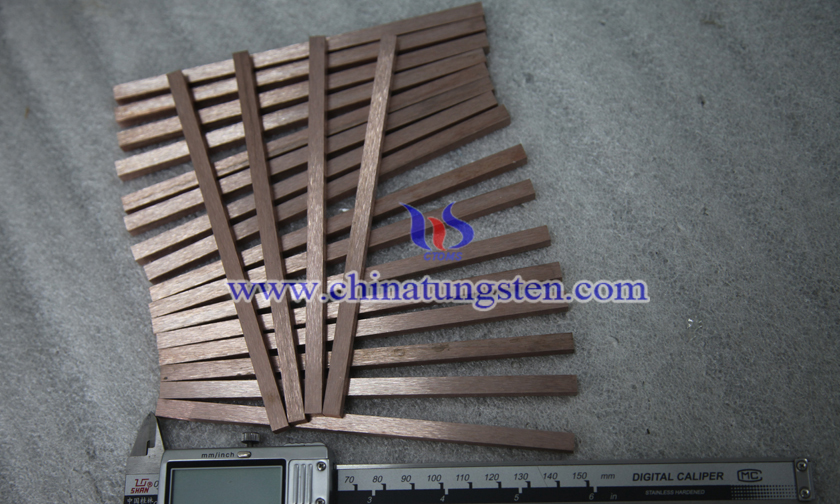

Tungsten Copper Bar Picture

The applications of tungsten copper polished bars are diverse include electrode for resistance welding, electrical discharge machining (EDM), high pressure discharge tube, even some military fields (instant high temperature material for piercing, missile insert and rocket ignitor).