The latest price of WC70Cu30 Φ7x300mm tungsten carbide copper rod is USD18.40/PC on June 16, 2023, EXW XIAMEN, CHINA.

| The basic trading conditions of Tungsten Carbide Copper Rod | |

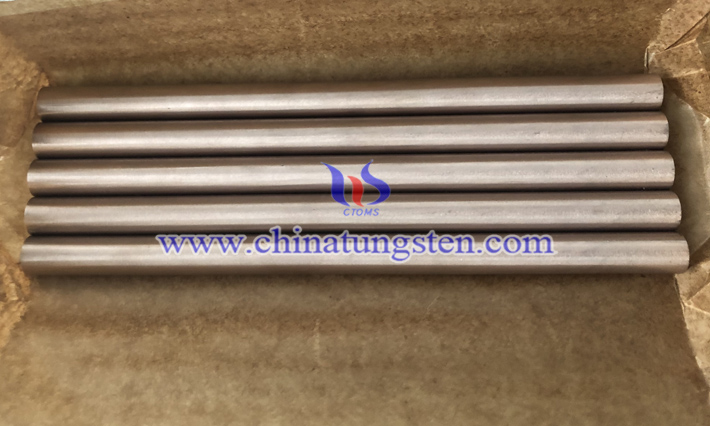

| Product name | Tungsten Carbide Copper Rod |

| Details | Dimension: Φ7x300mm

Grade: WC70Cu30 Formal contract quantity: 10pcs Quotation: USD18.40/pc Payment term: 100% T/T in Advance Delivery time: in 25 days |

| Contact | Tel.:+86 592 512 9595 +86 592 512 9696

Fax.:+86 592 512 9797 Email: sales@chinatungsten.com Business WeChat:

|

| Disclaimer | The above quotation is for reference only and is not the final order price and conditions. Please contact us directly for specific inquiry. |

What is Tungsten Copper Alloy?

Tungsten-copper alloys are pseudo-alloys of copper and the refractory metal tungsten. Since copper and tungsten are immiscible, the material consists of different particles of one metal dispersed in a matrix of another metal. As a result, the microstructure is a metal matrix composite rather than a true alloy.

Characteristics of Tungsten Copper Alloy

It combines the properties of two metals to form a material that is heat, ablation resistant, highly thermally and electrically conductive, and easy to process. It is also resistant to arc corrosion, mechanical wear and contact welding. Parts are made from tungsten copper alloy by pressing tungsten particles into the desired shape, sintering the compacted part, and finally infiltrating it with molten copper.

Tungsten Copper Alloy Grades

Common grades of this alloy contain 5% copper to 50% copper with tungsten in balance. The typical properties of an alloy depend on its composition. Alloys with less copper have higher density, higher hardness, and higher resistivity. Typical densities are 17.3 g/cm3 for WCu10 alloy and 12.2 g/cm3 for WCu50 alloy. WCu10 alloy has higher hardness and resistivity than WCu50 alloy of 260 HB kgf/mm2 and 6.5 µΩ.cm.

Tungsten Copper Alloy Applications

Tungsten copper products are meeting the increasing demands of high-tech applications, such as major electronic equipment, safety equipment, aviation and power generation, etc. Sheets and plates made from copper-tungsten alloys are used in many industries, including aerospace and power generation. Heat exchanger and cooler elements in electronic equipment as well as passive heat sinks, arches and vacuum contactors in high current equipment are made of this alloy.

More product details please visit:http://www.tungsten-copper.com/index.html